The Making of Dunoon Teaware

Dunoon's strength is in producing superior mugs that are objects of beauty and yet practical for everyday use. Join us and take a peek behind the scenes at Dunoon's headquarters to see how Dunoon products are made!

Dunoon Making Process:

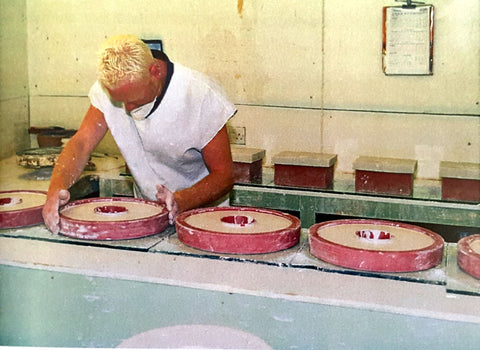

1. Making plaster moulds:

Plaster and water are mixed in a jug to a set ratio. The mix is pure into rubber cases and allowed to set.

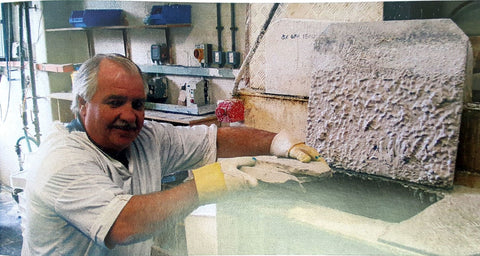

2. Making slip:

Clay is mixed with water to form a suspension known as slip.

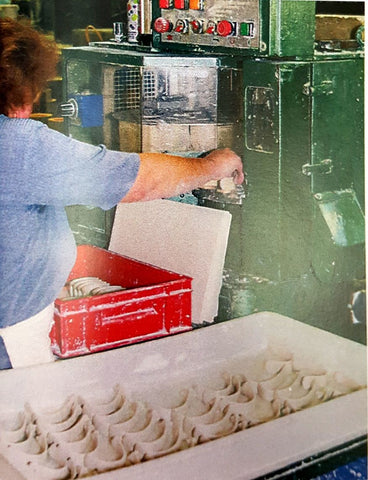

3. Filling the moulds with slip:

The slip is poured into moulds on the casting process. The moulds travel to the end of the casting belt in about five minutes.

4. Tipping the excess slip:

The excess slip is poured our and the mould allowed to drain.

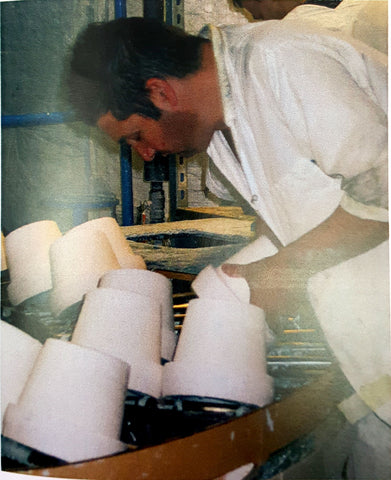

5. Opening the moulds

The moulds are opened and the soft clay mug is taken out

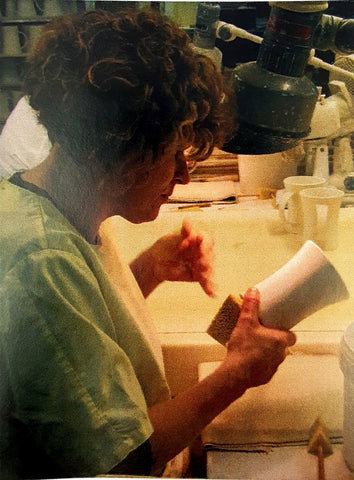

6. Sponging the clay mug:

The dry clay mug is sponged by hand to remove any imperfections.

7. Handle casting:

The hands are cast in a similar manner to the mugs in a two-part mould.

8. Sticking the handle:

The handle is dabbed into the slip and applied to the mug body by hand. The excess slip from around the handle joint is wiped away with a sponge.

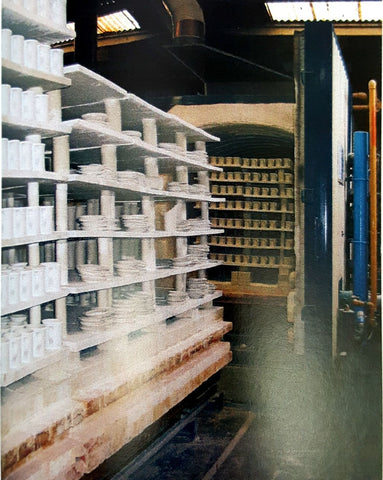

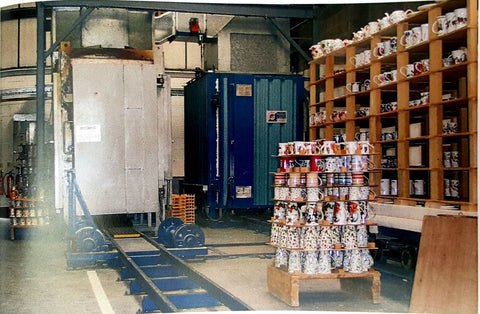

9. Placing & firing the clay mug:

The clay mugs are placed onto kiln cars which are wheeled into & out of the kiln.

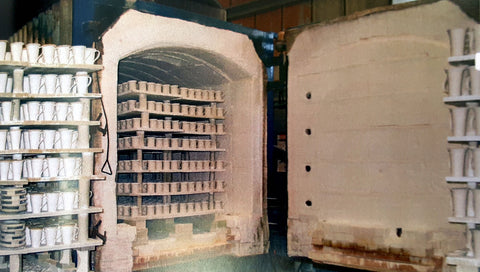

10. Biscuit kiln:

The firing takes eleven hours & is to 1220 degrees Celsius in a gas kiln.

11. Biscuit selection & grinding:

Once fired, the biscuit mugs are inspected, any faults are ground our using a sanding belt.

12. Polishing the biscuit mug:

Once fired, the biscuit mugs are inspected & polished in a vibro mill.

13. Applying the glaze:

Glaze is applied by hand dipping. the glaze is a glass powder suspended in water.

14. Glost Kiln:

The dried, glazed ware is placed onto the kiln cars. These are put into an elective kiln and fired to 1080 degrees Celsius for seven hours.

15. Reduction after firing:

From start to finish, the mug reduces in size. the clay mug starts our 12.5% larger than the finished fired mug.

16. Glost selection & grinding:

After lost firing each mug us inspected & any fault polished out before decorating.

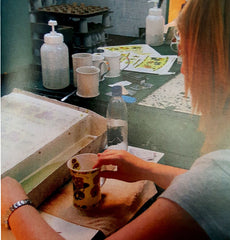

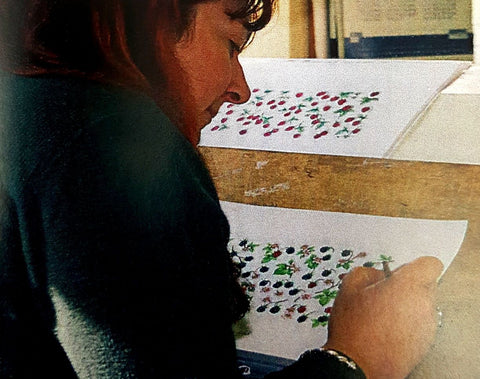

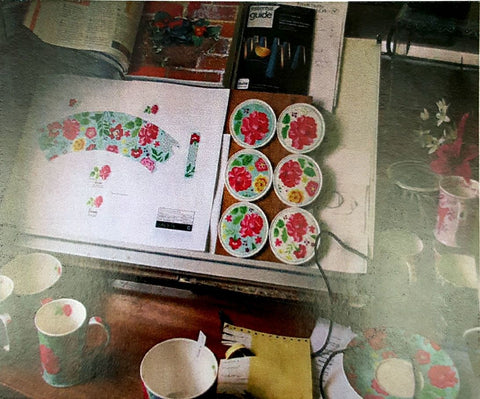

17. Lithograph standards:

Each mug is decorated to a set standard.

18. Applying the litho:

The litho is put into water which allow it to slide off the backing paper. After application, water and air are removed from beneath the litho with a squeegee.

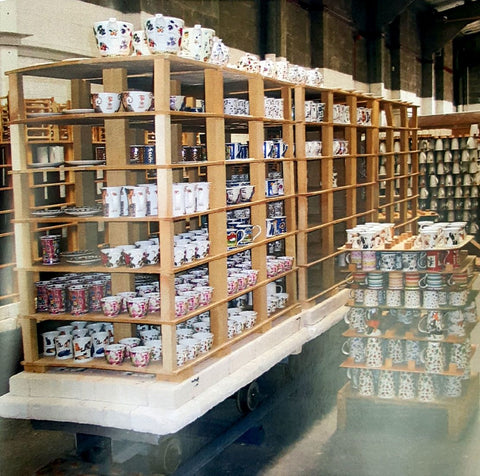

19. Firing the lithographed ware:

The lithographed ware is placed onto kiln cars and fired in an electric kiln to 825 degrees Celsius in five hours. During the firing the glaze softens and the enamel colours stick to the glaze surface.

20. Decorating kilns:

21: Final inspection:

The finished mugs are 100% inspected for faults. The Dunoon shield label is only applied to conforming mugs.

22. Packing & despatching:

The mugs are put into inner cartons & orders are made up for despatch.

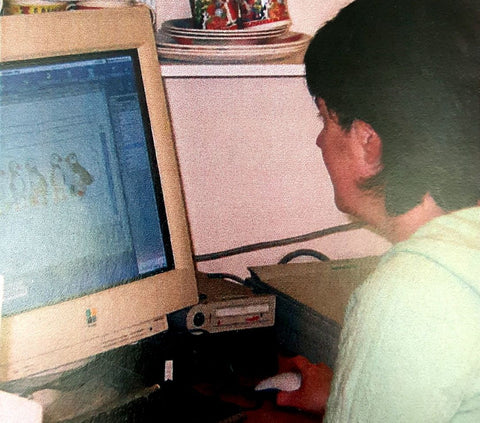

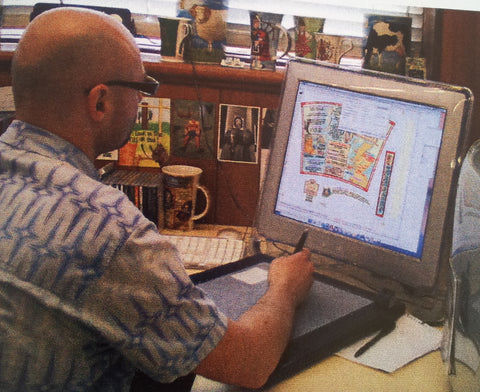

23. Design studio:

The design studio has a very important role to play ay Dunoon. Original design concepts are generated by our in-house designers and from feedback from our sales team.

24. Lithograph printing:

The original artwork is separated and individual screens are made before screen printing each colour down onto water slide transfer paper.

Leave a comment